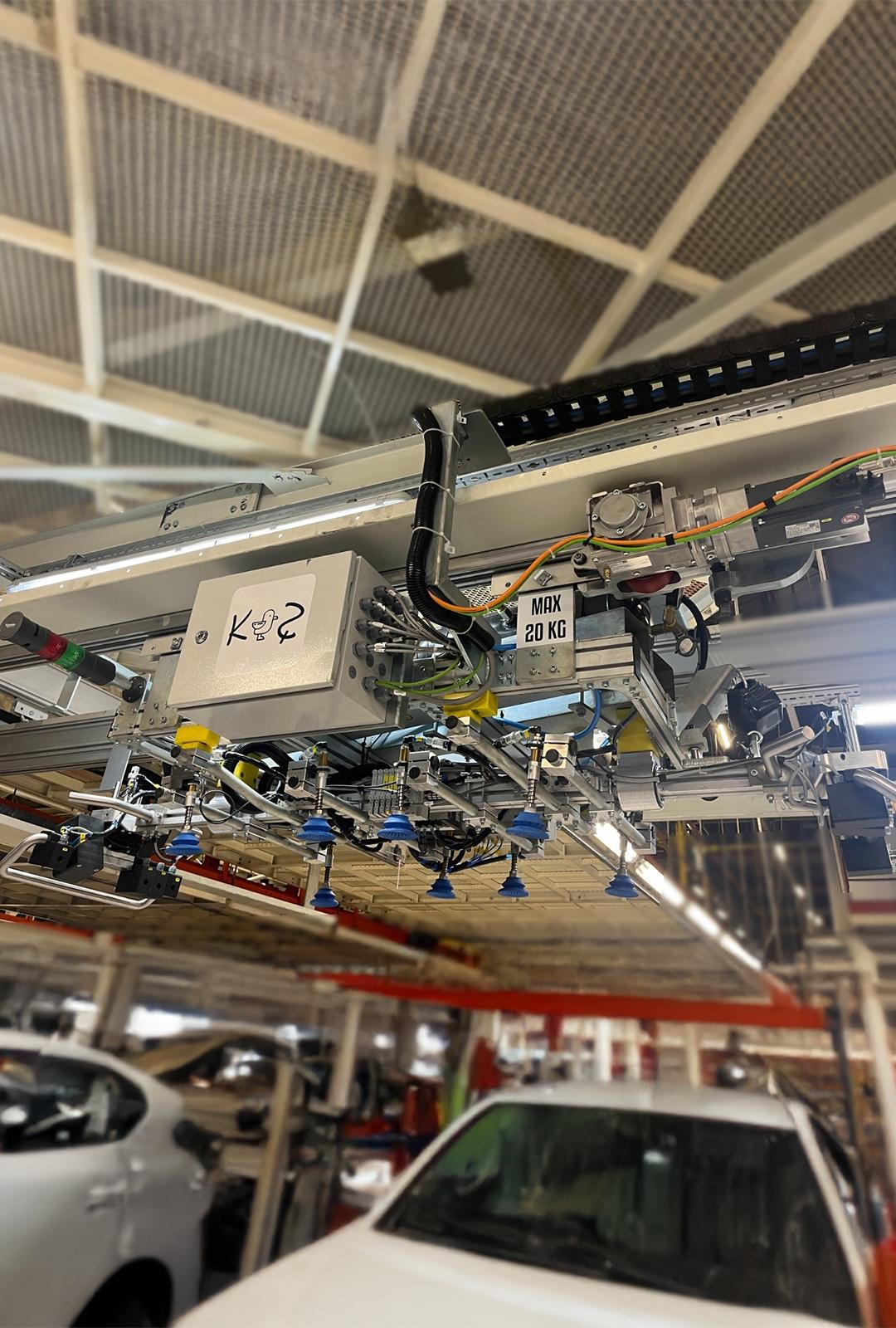

Automatic Loading Machines

Automatic loading and unloading machines enable the transfer, palletizing, or loading from pallet to line of all kinds of products and semi-products on various lines. They are designed according to your needs, with all analyses and simulations performed, manufactured, and delivered ready to operate in your factory.

System Features

Fully Automated Solutions

Provides continuous and reliable operation with minimal human intervention.

Flexible Design

- Modular Structure: Expandable according to needs

- Multi-Product Support: Adaptable for different product types

- Easy Configuration: Fast product changeover capability

Application Areas

Palletizing Systems

- Automatic Palletizing: Automatic stacking of products on pallets

- Mixed Palletizing: Placing different product types on the same pallet

- Layer Stacking: For optimal pallet fill rate

Machine Feeding

- CNC Feeding: Machine tool feeding and unloading

- Press Feeding: Sheet metal processing line feeding

- Furnace Feeding: Heat treatment line automation

Transfer Systems

- Inter-Line Transfer: Product transfer between production lines

- Warehouse Integration: Connection between warehouse and production line

- Quality Control Integration: Automatic inspection station feeding

Technical Specifications

Automatic Loading System Model

- Product Name: Automatic Loading System

- Maximum Load: Variable (product dependent)

- Maximum Moment: Variable (application dependent)

- Maximum Stroke: Variable (application dependent)

- Tare Weight: Variable (system dependent)

- Working Pressure: Variable (system dependent)

Performance Parameters

- Cycle Time: 3-15 seconds range (product dependent)

- Precision: ±1mm positioning accuracy

- Capacity: 5kg - 500kg product weight range

- Working Speed: 200-600 parts/hour

Mechanical System

- Servo Motor Drive: High precision and repeatability

- Linear Guide Systems: Precise motion control

- Robot Integration: Compatible with industrial robot arms

- Conveyor Integration: Compatible with existing transport systems

Control System

PLC Control

- Siemens/Allen Bradley: Industry standard PLCs

- HMI Interface: User-friendly operator panel

- Alarm System: Detailed error reporting

- Data Logging: Production data recording system

Safety Systems

- Safety Barriers: Operator protection

- Emergency Stop: Multiple e-stop buttons

- Light Curtains: Access control

- Interlock Systems: Safe operation guarantee

Gripper Systems

Vacuum Grippers

- Multiple Suction Cups: For large parts

- Flexible Suction Cups: For curved surfaces

- Safety Valves: Safe release during power cut

Mechanical Grippers

- Pneumatic Actuator: Fast and reliable gripping

- Electrical Actuator: Precise force control

- Custom Fingers: Product geometry-specific design

Magnetic Systems

- Electromagnetic: Controlled holding/releasing

- Permanent Magnetic: Energy-saving solution

Sensor Technologies

Position Sensors

- Laser Distance Meter: Precise position detection

- Vision System: Position control with image processing

- Proximity Sensors: Proximity detection

Quality Control Sensors

- Dimension Measurement: Automatic dimension control

- Weight Control: Weight measurement with load cell

- Surface Control: Defect detection with image processing

Software Features

Programming

- Easy Programming: Drag & drop interface

- Recipe System: Product-based setting records

- Simulation: Offline programming and testing

Reporting

- Production Reports: Detailed performance analysis

- Maintenance Tracking: Preventive maintenance planning

- Efficiency Analysis: OEE calculations

Integration

ERP Integration

- Production Plan Receipt: Automatic order processing

- Inventory Tracking: Real-time inventory update

- Quality Data: Quality data transfer to system

MES Integration

- Production Tracking: Real-time production status

- Traceability: Product traceability

- Performance Monitoring: Real-time performance data

For automatic loading solutions specific to your production process, contact us.